MACHINES

TUNNEL PASTEURISER-COOLERS

Pasteurise and cool tins, glass containers, flexible multilayer bags

Video recorder with Smart Card for recording:

- pasteurisation water temperature

- cycle time

- steam pressure

- hot water pump delivery pressure

- pre-cooling water temperature

- tower water temperature.

Electrical panel with PLC and wiring

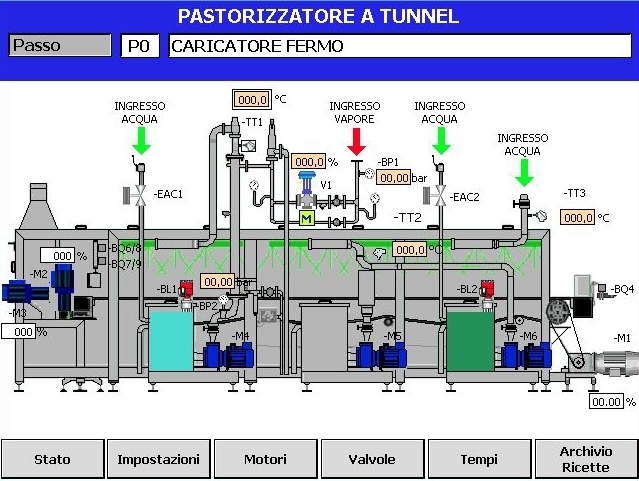

Electrical panel with PLC and 10” TOUCH SCREEN operator panel in stainless steel cabinet to CEI-CE standards with:

- main switch

- emergency button

- cycle start button

- remote switches and motor protectors

- low-voltage auxiliary circuits.

Electrical connections from the panel to the motors and other electrical utilities, with IP65 sealed flameproof cables, open ducts in stainless steel wire.

TUNNEL PASTEURISER-COOLER

Tunnel tunnel pasteurisers-coolers are used for heat treatments on static containers with spraying water rain heat exchange system by means of which the best time/temperature ratio is obtained.

In the pasteurisation section, the containers are hit with misty rain at 95/98 °C constant throughout the section.

The cooling section is divided into two or more zones with water at different temperatures.

The body of the machine is made with AISI 304 stainless steel sheet, with feet and reinforcements in tubular profiles.

Equipped with adjustable feet and lids fitted into hydraulic sealed channels.

Polypropylene conveyor belt with modular elements.

Special combs are installed at the infeed and outfeed of the tunnel to facilitate the passage of the containers, eliminating the risk of jamming and/or overturning.

The belt drive is assured by gear motor with servo-ventilated motor and inverter variator, with chain drive.

Sprayers with large anti-clogging passages mounted with snap couplings on manifold pipes.

The machine is equipped with hinged shutter conveyor belts for the infeed and outfeed of the containers and a tin aligner feeder in parallel rows, synchronised with the belt speed; equipped with a pusher driven by pneumatic jacks, a tin stop device and an electronic tin counter for activating the pusher for complete rows.

Temperature probe Pt100 installed in the pasteuriser tank.

High automation

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer and various production capacities

EFFICIENCY

Special sprayers are used that guarantee the correct rain spraying and distribution

VERSATILITY

They can handle most food containers. Automatic infeed systems available.

AUTOMATION

The system is fully automatic and each process parameter can be configured on the touch screen operator panel

SAFETY

Our tunnel pasteurisers-coolers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking