MACHINES

ROTARY COIL DEFROSTERS-PREHEATERS

Continuously defrost fruit pulp in granular form.

Rotary coil defrosters/preheaters are machines used to defrost fruit in granular form

Products that can be processed in our rotary coil defrosters

ADVANTAGES AND SPECIFIC FEATURES

AUTOMATION

In the most advanced versions, it is controlled by a PLC with touch screen operator panel and is completely automatic.

The operating parameters such as speed and temperatures are fully programmable.

VERSATILITY

Can be used with any vegetable or fruit type.

RELIABILITY

Designed for durability and low maintenance

PROCESS CONTROL

The different heating systems can be activated independently and simultaneously. Together with the variable rotation speed of the trough, the heat treatment is controlled promptly and in a modular manner.

SAFETY

All our defrosters are equipped with all the safety systems necessary to comply with the requirements required by European directives and comply with the CE marking.

PED-certified pressure equipment

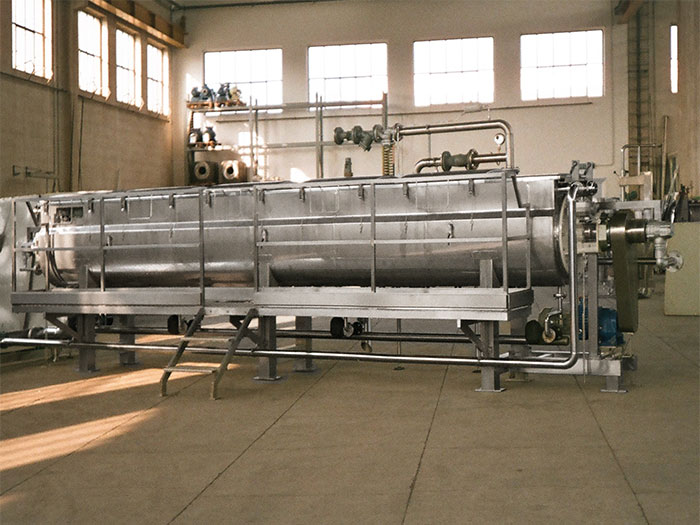

ROTARY COIL DEFROSTERS-PREHEATERS

Machine with trough structure, heated by steam, or hot water if required, through the internal surface of the structure equipped with cavities, the hollow rotating shaft and the coil connected to it.

Optionally the following heating systems can be used, even partially associating them:

- Indirect heating through the steam jacket and/or shaft with rotary coil.

- Direct steam injection heating through the steam injectors.

- Mixed heating.

Operation of the plant

The product enters the machine from one end and exits continuously from the opposite side through an opening on the bottom and connected to a volumetric extraction pump.

Pump speed controlled by the level regulator.

The machine is composed of two “U” shaped metal sheets, one inside the other, forming the supporting body and the cavity, inside which the heating fluid circulates.

The two ends are closed by two openable heads, specially shaped to form the support of the rotating axis.

It has a series of watertight lids that can be opened on the hinge and fixed by means of snap hooks.

A series of special steam injectors are placed on the machine bottom generator.

Each injector is equipped with a shut-off valve.

A rotating shaft, consisting of a tube through which steam circulates, on which a helical spiral tube is mounted for heating and feeding the product.

a

Gear motor and speed variator with inverter with chain drive protected by a guard.

Volumetric pump for product extraction, driven by gear motor and inverter variator.

Electronic level regulator for controlling the pump.

Three-way sanitary diverter valve for product recycling.

Washing balls with tap.

Body insulated with rock wool and stainless steel coating.

Accessories, automatic valves, control and regulation of variables in the field.

Electrical cabinet, containing the control and protection equipment for the motor and the instrumentation.

The machine is completely made in AISI 316 stainless steel and mirror polished in the parts in contact with the product, AISI 304 in the others.

Different models, sizes and technical characteristics related to the production capacity are available.

High production capacities