MACHINES

HOT BREAK PREHEATERS

Integrated tomato juice extraction systems with HOT-BREAK technology

HOT-BREAK FORCED-CIRCULATION PREHEATER

HOT-BREAK ROTARY COIL PREHEATER

Our HOT-BREAK forced-circulation preheater is used for rapid heating of re-circulating tomatoes with hot shredding, in order to block the action of pectolytic enzymes and obtain a finished product of high viscosity and consistency.

They are built in different models with different production capacities.

Finished product of high viscosity and consistency

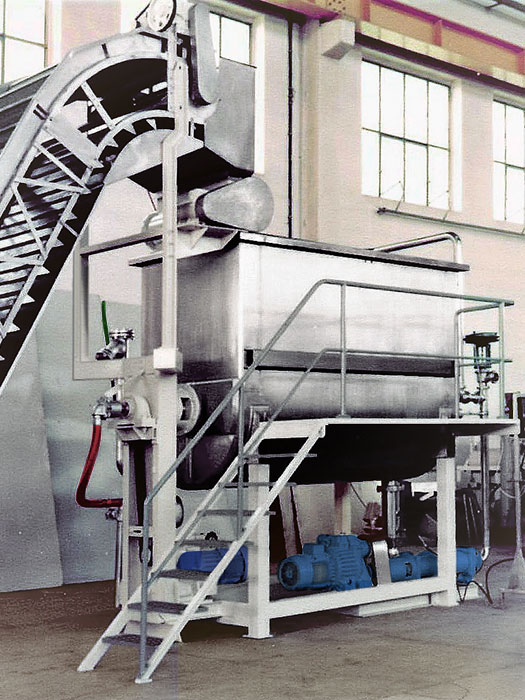

HOT-BREAK FORCED-CIRCULATION PREHEATER

For rapid heating of re-circulating tomatoes with hot shredding, in order to block the action of pectolytic enzymes and obtain a finished product of high viscosity and consistency.

The system is composed of:

- A pump for feeding whole tomatoes with a stainless steel storage tank.

- An "IN LINE" shredder made in AISI 304 stainless steel, mounted on a self-supporting structure.

- Knives in special hardened steel.

- Storage tank in stainless steel.

- Large capacity horizontal centrifugal pump made of stainless steel, for product circulation.

- A vertical tube bundle heat exchanger, for heating the product, entirely made in stainless steel.

- A pump for the extraction of the inactivated product and to feed the next juice extraction unit, not part of the installation.

- A pump for the partial recycling of the hot product into the fresh tomato hopper.

- A galvanised steel structure to support the entire assembly.

- An electrical control panel, made in stainless steel containing the electro-pneumatic control and adjustment equipment, PLC and touch-screen.

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer and of various production capacities

QUALITY

Sized to preserve the organoleptic properties of the processed product as much as possible

SAFETY

Our pasteurisers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking

PED-certified pressure equipment

HOT-BREAK ROTARY COIL PREHEATER

Tomato juice extraction with HOT-BREAK technology

For rapid heating of tomatoes with hot shredding, in order to block the action of pectolytic enzymes and obtain a finished product of high viscosity and consistency.

Made in AISI 304 stainless steel, with trough product storage tank with sealed opening lids.

Rotary coil immersed in the product, steam heated, driven by a variator.

The comb shredder is installed directly on the tank to chop fresh tomatoes mixed with recycled hot product.

Volumetric product extraction and recycling pump.

Support frame and assembly of the unit, made in stainless steel with service gangway and access ladder.

Automatic control of variables in the field with digital instrumentation.

Finished product of high viscosity and consistency

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer and of various production capacities

QUALITY

Sized to preserve the organoleptic properties of the processed product as much as possible

SAFETY

Our pasteurisers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking

PED-certified pressure equipment