PELLACINI TODAY

Research, technology, design, engineering

THE IDEAL PARTNER

Our primary aim is to guarantee customers the best production performance throughout the life cycle of our systems.

We focus our business on research, technology, design and engineering.

Our plants are constructed by highly specialised workshops specifically for each project, and we oversee each production phase. In this way we respond concretely to the needs of productivity, cost-effectiveness, safety and environmental sustainability.

We select the production workshops with a view to obtaining the highest quality at the best cost, according to the "TAILORING SYSTEM" method.

Our technology is extremely flexible, reliable, easy to maintain and always at the forefront of innovation.

We provide complete assistance: from commissioning to testing, up to legal certifications.

We guarantee timely and accurate after-sales service, everywhere.

Our archive includes the designs of all the machines and plants built over time.

We provide a complete Service

Technological consulting

for end customers

We put all our experience gained in the field and resulting from the development of our machines and systems at the disposal of our customers.

Supporting customers in the production phases is of primary importance to us, and we offer assistance and support on the technological processes required to obtain high quality products.

We have adopted an integrated management system that includes ISO 9001:2015 quality certification and FCM management. (Food Contact Materials)

We are members of the voluntary EHEDG consortium.

The European Hygienic Engineering & Design Group (EHEDG) was founded in 1989 as a non-profit consortium bringing, together equipment manufacturers, food manufacturers, food industry suppliers, research institutes and universities, public health authorities and government organisations.

The main objective of EHEDG

is to promote food safety through the improvement of hygienic design and engineering in all aspects of the food industry.

OPTIMISATION OF PRODUCTION PROCESSES

Machinery and plant design

We offer a machine and system design service for food producers, to create special and bespoke applications using our experience as manufacturers.

Collaborating with our customers, we help them to complete and optimise the production processes necessary to create innovative products.

We provide a complete Service

RESEARCH & DEVELOPMENT

& CAE SIMULATIONS

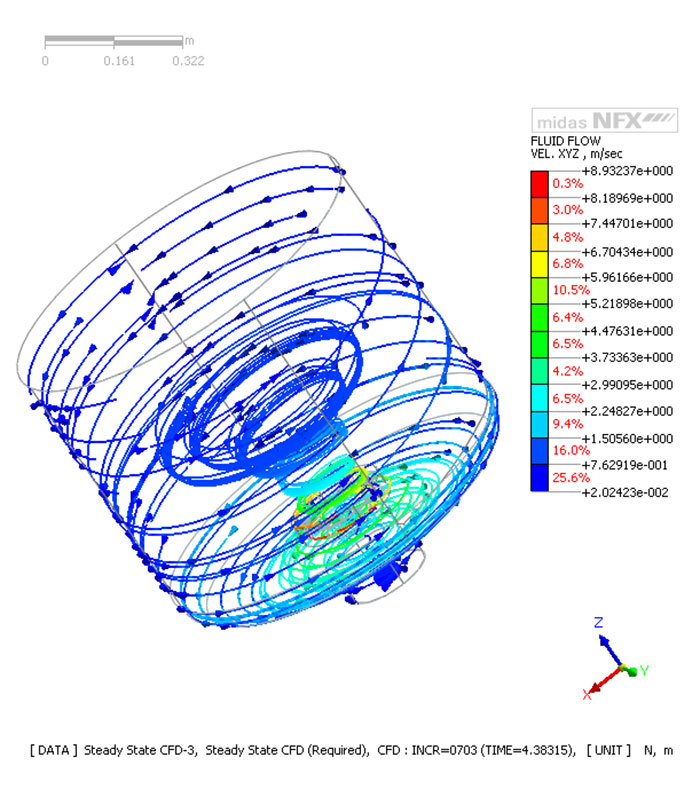

We devote a lot of time to research with a view to perfecting our machines and systems.

Our engineering department uses the latest design software for both mechanical design and mechanical and fluid dynamics simulation.

OPTIMISATION OF PRODUCTION PROCESSES

PROCESS SOFTWARE

DEVELOPMENT

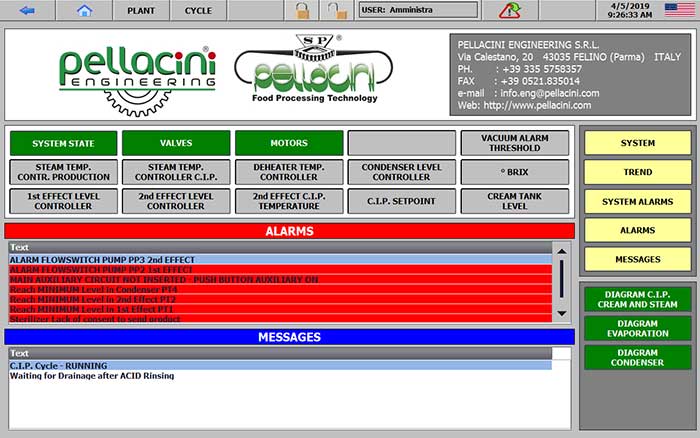

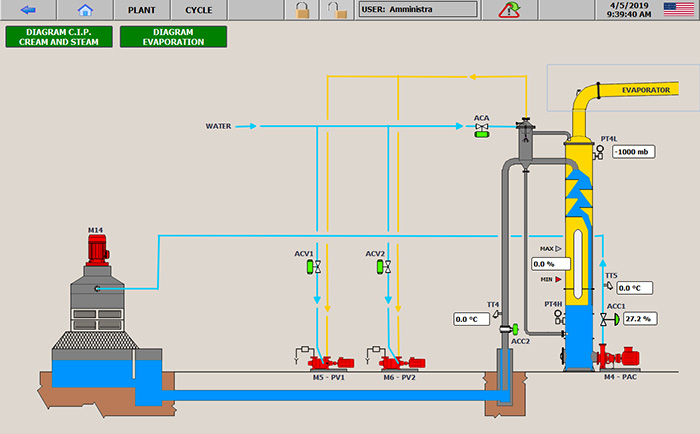

We develop all the process automation software installed in our machines and systems in-house.

The software installed on PLC and HMI (operator panels) is used to control the plants and machines with a minimum labour inputs.

The software is continually updated to obtain increasingly efficient processes in terms of product quality.

Our systems can be equipped with the latest SCADA systems and can be integrated into the customer's management systems with a view to Industry 4.0

We put our experience at the disposal of our customers to develop bespoke automation software for existing systems that need to be updated.

OUR MARKETS

We work in the Italian and all major international markets: Europe, South America, North Africa, the Middle East and the Far East.